In this section we are going to discuss the details of how a Stacked Deep Well Pump System works.

Highlights of a Stacked Deep Well Pump System

- Well has a Static Water Level up to 160 feet.

- Must be mounted directly above the well.

- Stacked Cylinder is connected directly to pipe from the electric submersible pump system resulting in them being “stacked”.

- Only used in cased wells that are typically 4” – 5” in diameter.

- Used in conjunction with an electric submersible pump installed in the same well casing.

- Water flows through the electric pump’s water inlet to feed the entire system.

- Water from the electric submersible pump exits the well above ground.

- Moving the handle up/down actuates the piston assembly inside the cylinder which lifts the water.

- Can lift water through the system from 160 feet below the surface.

- Cylinder sizes determined by both static water level and pump GPM primarily.

- Requires rigid pipe with drop rod inside from the stacked cylinder to the bottom nipple of the pump head.

- Cylinders are inside a protective support structure and placed 20 feet below the static water level.

Details

Well Casing with Liner

A Bison Deep Well Pump System is typically installed Side-By-Side an electric pump system in the same well casing. This requires the well casing/liner to be large enough to accommodate both pump systems. However, for customers with a small casing diameter (4” – 5”); refer to Well Casing Measuring) or well liner, the deep well pump system cannot be placed alongside the existing electric system. Therefore, we must place the two systems stacked atop each other, so that both systems can fit inside the confined space. This is when we recommend a Stacked Deep Well Pump System.

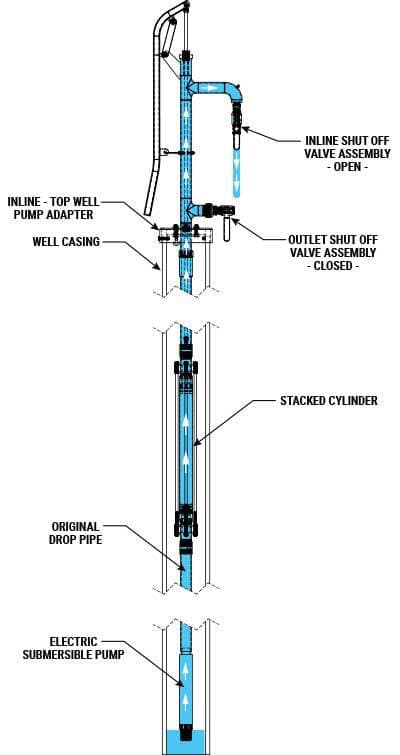

A Stacked Deep Well Pump System is a Lift Pump consisting of a special pump head which sits atop the well casing, PVC pipe and rod that reaches approximately 20 feet below static water level, and a structurally supported cylinder which connects to the electric submersible pump pipe. The water flows through the electric submersible pump water inlet upward through the Bison Stacked Cylinder, pipe & rod, and eventually to the pump head above ground.

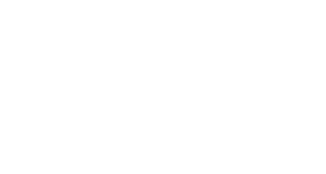

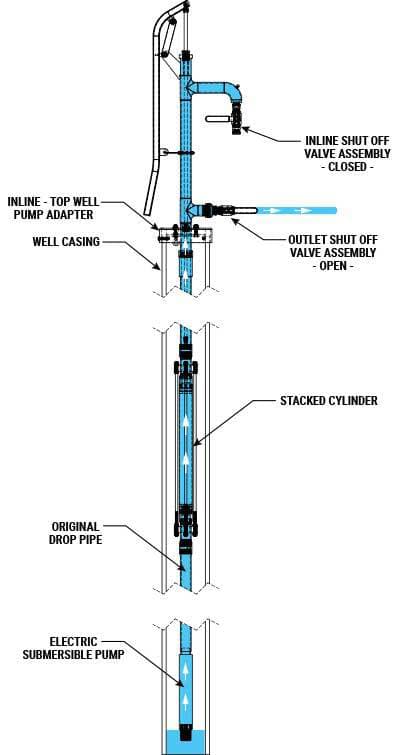

Inline Pump with Shut-Off Valve

During operation, only one of the two systems, electric or manual, can be used at any time. The pump head comes with a shut-off valve on the spout. The electric submersible pump water exit connection requires an Inline – Top Electric Submersible Pump Outlet Connection Shut-Off Valve Assembly which can be provided by Bison Pumps. To use the manual Bison Pump system, the electric system valve must be turned OFF and the valve on the spout turned ON (image A). The Bison Pump system will function normally with water exiting the spout with this ON/OFF scenario. When using the electric submersible pump, the two valves must be reversed: water exit valve ON and spout valve OFF (image B).

During power outage situations, if you wanted to have Pressurized Back Up Water, then you would leave the shut-off valves set for electric pump operation. This setting directs water inflow out the pump head and into the water line. With the water line going to the pressure tank, the Bison Pump is able to pressurize the tank and thereby provide you with back up water inside your home that is usable from any water feature such as a toilet or sink.

Stacked Cylinder Showing Protective Support Structure

To accomplish this design, we structure the system so that the electric submersible pump is at the bottom of the system placed at its normal depth in the well, typically near the bottom. The Stacked Cylinder is placed 20 feet below the static water level to allow for fluctuations in the water table throughout the year. The pipe from the electric submersible pump is used to connect the two systems. Therefore, the electric system pipe will be directly connected to the water inlet at the bottom of the Stacked Cylinder. Because the extra weight of the electric submersible pump system that is attached to the cylinder puts a great strain on the cylinder and could easily pull the components apart, we built a protective support structure and installed the cylinder inside. The electric submersible pipe is actually connected to the water inlet of this support structure. Please note, however, that if the electric submersible pump system uses galvanized pipe, the weight becomes too great for the PVC pipe to support. Therefore, in those circumstances, we must recommend using galvanized piping throughout the system. You will need to speak with a Bison Pumps representative to discuss this issue.

From the Stacked Cylinder placement 20 feet below the static water level up to the bottom nipple of the pump head water inlet, the system uses 1 1/4” Schedule 120 PVC drop pipe and rod to connect the two system components. The Stacked system gets water to the surface the same way as a standard lift pump system with one exception. Since the electric submersible pump is attached to the water inlet of the Stacked Cylinder, the water inlet of the electric submersible pump becomes the water inlet for the entire system. There will not be a filter that comes with the Stacked Cylinder. All filtering will be performed by the electric submersible pump’s filter system.

Since the water flow from the electric submersible pump will pass through the Stacked Cylinder, there are some size limitations of the electric pumps to prevent damage to the Bison Pumps cylinder. Bison Pumps offers these cylinders in two sizes: 2” and 2.5”. The 2” cylinder can be connected to an electric submersible pump up to 12 gpm (gallons per minute) at a maximum static water level of 160 feet. The 2.5” cylinder can handle up to 28 gpm at a maximum static water level of 110 feet. View Stacked Cylinder Selection Chart.

Water Outlet Above Adapter

Another difference in the operation of the Stacked system compared to the Side-By-Side, is water output from the electric submersible pump exits through the combined Stacked/Electric piping system. With the current Bison Pumps Stacked pump system offering, Inline – Top, the water from the electric submersible pump exits the well through a connection on the body of the pump head. This is because the two systems are connected and all water flow must pass through the electric system first, then the Bison Pumps cylinder and pipe up to the pump head as shown in the diagrams above. This means that the water exits above ground and is subject to freezing if arrangements have not been made at the well site to maintain temperatures above freezing. This is a major consideration when deciding if the current Stacked Pump, Inline – Top system, is to be used.

Installed Inline – Top Deep Well Pump

The Stacked deep well pump system comes with a Standard well pump adapter to attach the pump head to the well casing that replaces your well cap and provides a seal to protect your well water from contaminants by utilizing a bottom plate kit. The bottom plate kit consists of a rubber gasket and stainless-steel bottom plate. The gasket expands to create a seal when the four attachment bolts are tightened.

Considerations

- The GPM of the electric pump directly impacts the Stacked Cylinder sizing. Verify the output of your system as a part of your data gathering.

- Well casing height above ground is recommended to be 12 inches to 18 inches. This height will place the pump handle in a comfortable pumping height.

- If the well casing is PVC, the wall thickness can become an issue. Typical well casing would be schedule 40 or 80, either of which may be too weak to absorb the pumping action of the handle. Evaluate the strength of your well casing at the recommended height. Often, we find that customers need to provide some type of support for their PVC well casing when the wall thickness is thin.