Measuring the Well Casing

Turn off the electricity if you have an electric submersible pump before removing the well cap.

Turn off the electricity if you have an electric submersible pump before removing the well cap.

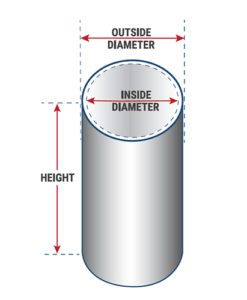

Outside Diameter

With the well cap off, put one end of the measuring tape on the outer edge of the well casing. Pull the tape straight across to the other side. While holding the end with one hand, move the other end back and forth across the opposite casing end. You will see the largest measurement reoccur. That figure will be the Outside Diameter of the well casing.

Sometimes it is difficult to remove the well cap to get this measurement. Especially if you are at the quote stage, we can calculate pricing with only the Outside Diameter. To get this figure another way is to measure the circumference of the well casing. This is the distance around the outside of the casing. We divide that figure by Pi and the result is the diameter of the well casing. An example would be a circumference of 18.84” divided by Pi (3.14) = 6” (most common well casing size).

Before we can determine the actual pump system for your application, we must have the Inside Diameter measurement for the reasons stated above.

Inside Diameter

Move the end of the measuring tape to the inside of the well casing and perform the same back and forth movement as described above. This time note the largest number on the inside of the well casing. This figure is your Inside Diameter of the well casing.

We can use the Outside Diameter for pricing only. To place an order, we must know the Inside Diameter.

Well Casing Height

Using a tape measure, extend it from the ground to the top of the well casing. For ease of pumping it is recommended that this measurement be between 18 and 24 inches.

Why It Matters

After Static Water Level, the well casing size is the next most important feature in determining the proper Bison Pump system for you. Bison Pumps’ Side-By-Side Deep Well Pump systems require sufficient space inside the casing for the Drop Pipe and Rod and Cylinder to fit inside the well casing. In some cases the Drop Pipe’s bell diameter is the largest dimension. For example, 1” NPT drop pipe bell diameter is 1.75 inches. If it is paired with the 1.5” cylinder, then 1.75” is the dimension that must fit inside the well casing. Therefore, the smallest well casing we can accommodate is 2”. The 1 1/4” NPT drop pipe bell is 2.25 inches in diameter. If space is limited we can pair a 2” cylinder with 1” NPT drop pipe to have a 2” limitation inside the well casing. For the 2.5” and 3” cylinders, the cylinder diameter becomes the limiting factor.

If your well has an electric submersible pump installed, then more space inside the casing will be required to allow it and the Bison Pump deep well pump system to occupy the inside of the well casing. Items to consider include:

- Bison Pump system

- Cylinder Diameter

- Pipe bell diameter

- Plus Electric Submersible Pump system

- Electric pump water output pipe coupling diameter if the water exits the top of the well cap, or

- Pitless adapter width if the water exits underground.

In addition, Bison Pumps Deep Well Pump systems include a pump head with a new well adapter welded to the pump body. With this pump head comes a rubber gasket that seals the pump head to the well casing. This prevents well contamination. To size this gasket properly, we need to know the inside diameter of the well casing. We adjust the size of these gaskets every 1/4”.