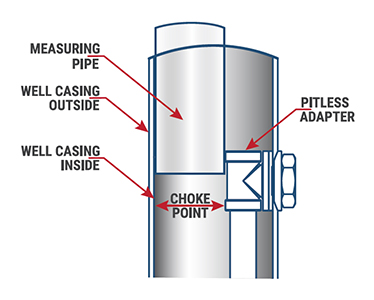

The Choke Point is the smallest measurement inside the well casing through which the cylinder and drop pipe must pass. For most Side-By-Side Deep Well Pump Systems this is one of the measurements that will help define the system designed for a particular well setup.

Choke Point

In our Choke Point diagram, we show the most common choke point. This is where the pitlless adapter is installed inside the well casing. The pitless adapter is installed just below the frost line and therefore is often not easily accessible from the top of the well. One of the most effective ways to “measure” the choke point distance is to obtain a pipe that approximates the size of the cylinder that relates to your static water level. For instance, if your static water level indicates that you can use a 3 inch cylinder then locate a 3 inch diameter pipe. Lower it to the pitlless adapter and attempt to slide it past the choke point. If it will not slip by without being forced then the 3 inch cylinder will not fit either. Reduce the size of the pipe by 1/2 inch and repeat until the pipe slides easily past the choke point. That will be the size cylinder that your well casing can accept.

Measuring the Inside Casing Diameter

If your well does not have an electric pump or the water from your electric pump exits the well through the well cap, then your choke point will be different. With no electric pump installed either the inside diameter of the well casing or a liner is your choke point. Simply use a measuring tape to determine the diameter of the smallest pipe through which the system will be installed.

If you have an electric submersible pump system that exits the top of the well casing then your choke point will be the inside diameter of the well casing (or lining) less the diameter of the pipe from the electric submersible pump. For example, if the electric pump pipe is 1 inch poly pipe and the well casing inside diameter is 6 inches then you have 5 inches for the Bison Pumps system. However, if the electric pump’s pipe is 1 1/4” PVC then you have to consider the coupling diameters. Those typically are approximately 2.5 inches (they vary by manufacturer and type). Therefore, in the example above, with a 6 inch inside diameter less 2.5 inches leaves 3.5 inches for the Bison Pump system which is still plenty of room for our largest cylinder.